KT board is a new material made of polystyrene (PS) PS particles through foaming to form board core and surface lamination. The board body is straight, light, not easy to deteriorate, and easy to process. It can directly mount photo pictures and adhesive back stickers on the board. It is widely used in signboard production, corporate culture wall advertising, display and promotion, advertising design, and packaging. Its material is light, flat, easy to process, and low cost. The standard size is 1.22m wide and 2.44m long.

Nowadays, with the development of society and the improvement of people’s living standards, KT board is often used in indoor layout, especially suitable for office layout, such as large-scale KT board decorative painting.

In addition, the KT board is widely used in indoor and outdoor advertising, especially for large-scale unified publicity activities.

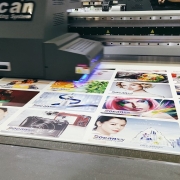

Whether the KT board is used outdoors or indoors, it usually depends on relevant combined materials and fabrication processes. Indoor KT board advertising printing is generally printed with an indoor photo back glue, laminated with matt film or glossy film, mounted on one side or double sides of the KT board with a cold mounting machine, while those placed outdoors are generally printed with outdoor photo self-adhesive, laminated with matt film or glossy film, which can also be mounted on one side or double sides of the KT board with a cold mounting machine.

Regarding the price of KT board printing, it is relatively more favorable compared with that of PVC foam board, and the printing effect is remarkable. However, KT board printing is suitable for short-term use. If used for a long time, it is easy to blister due to the reasons of the board texture itself and the change of weather. We suggest replacing the KT board with a PVC foam board for long-term use.

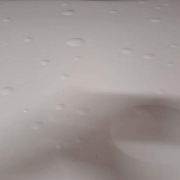

Reasons for blistering of KT board

Bubble phenomenon: after mounting the photo picture on the KT board, the picture film is arched to form bubbles.

Bubble cause:

- The ripening period of the foam core is short.

- The PS film on the board surface is too thin.

- The glue on the back of the picture reacts with the PS film.

- The environment is too hot and cold, and the temperature difference between day and night is too big.

Leave a Reply

Want to join the discussion?Feel free to contribute!